The Cool Roof Revolution: A Decade of Transformation

In the relentless battle against rising energy costs and the escalating effects of climate change, businesses are increasingly seeking innovative solutions to minimize their environmental footprint and maximize profitability. One such solution, gaining traction over the past decade, is the application of high-performance reflective roof coatings on commercial buildings. These ‘cool roofs’ promise significant energy savings, extended roof lifespans, and a tangible contribution to sustainability goals. But do they live up to the hype? This comprehensive guide delves into the world of reflective roof coatings, exploring their benefits, application, and long-term viability, providing a clear picture for commercial property owners and managers seeking a smart investment.

For commercial roofing, the integration of sustainable roofing solutions is no longer a niche trend but a strategic imperative. Reflective roof coatings represent a practical approach to achieving energy efficiency goals while simultaneously addressing concerns about urban heat island effects. These coatings, designed to reflect a substantial portion of solar radiation, directly translate into reduced cooling loads for buildings. This not only lowers operational expenses but also decreases the strain on local power grids, particularly during peak demand periods.

The adoption of cool roof benefits extends beyond immediate cost savings, contributing to a broader commitment to environmental stewardship and enhancing a company’s public image. Understanding the nuances of commercial roof energy savings is crucial for making informed decisions about reflective roof coatings. The effectiveness of these coatings is influenced by factors such as climate, building design, and the type of coating used. While white coatings are generally the most reflective, advancements in technology have led to the development of colored coatings that still offer significant solar reflectance.

Furthermore, the long-term performance of a reflective roof coating depends heavily on proper roof coating application and maintenance. Regular cleaning to remove dirt and debris is essential for preserving reflectivity and maximizing energy savings. Therefore, a comprehensive approach that considers both the initial investment and ongoing maintenance is necessary to realize the full potential of cool roofing solutions. Beyond the immediate financial benefits, reflective roof coatings contribute to a more sustainable built environment. By reducing energy consumption, these coatings help lower greenhouse gas emissions and mitigate the impact of climate change. Moreover, some reflective roof coating products are manufactured using recycled materials, further minimizing their environmental footprint. As businesses increasingly prioritize sustainability, the adoption of cool roofs aligns with broader corporate social responsibility initiatives. The future of roofing is undoubtedly leaning towards sustainable practices, and reflective roof coatings are poised to play a significant role in shaping that future. By embracing these technologies, businesses can demonstrate a commitment to both environmental and economic sustainability.

How Reflective Roof Coatings Work: The Science of Staying Cool

Reflective roof coatings operate on a deceptively simple yet profoundly impactful principle: they reverse the heat absorption process inherent in conventional roofing materials. Traditional dark-colored roofs, ubiquitous in commercial construction for decades, act as solar sponges, absorbing a significant percentage of incoming solar radiation. This absorbed energy manifests as increased surface temperatures, often soaring to unbearable levels during peak sunlight hours, which directly translates to a heightened demand for air conditioning to maintain comfortable indoor environments.

This cycle contributes significantly to commercial buildings’ energy consumption and operational expenses. Reflective roof coatings, conversely, are engineered to minimize solar heat gain. The efficacy of reflective roof coatings hinges on two key properties: high solar reflectance and high thermal emittance. Solar reflectance, often expressed as a percentage, quantifies the amount of solar energy a surface reflects away from the building. The higher the percentage, the less heat is absorbed. Thermal emittance, on the other hand, measures a material’s ability to release absorbed heat.

Even with high solar reflectance, some heat absorption is inevitable; thermal emittance ensures that any absorbed heat is efficiently radiated back into the atmosphere. Together, these properties ensure that a roof remains significantly cooler than its traditional counterpart, directly reducing the amount of heat transferred into the building’s interior and unlocking substantial commercial roof energy savings. This reduction in heat transfer yields a cascade of cool roof benefits, extending beyond mere energy savings. Lower cooling energy consumption directly translates to reduced strain on HVAC systems, prolonging their lifespan and minimizing maintenance costs.

Furthermore, reflective roof coatings contribute to mitigating the urban heat island effect, a phenomenon where urban areas experience significantly higher temperatures than surrounding rural areas due to the prevalence of dark, heat-absorbing surfaces. By reflecting sunlight back into the atmosphere, these coatings help to lower ambient temperatures, improving overall environmental conditions. Proper roof coating application is critical to ensuring optimal performance and realizing these benefits, requiring careful surface preparation and the use of appropriate application techniques. As sustainable roofing solutions become increasingly vital in the face of climate change, reflective roof coatings offer a tangible and effective means of reducing a building’s environmental footprint while simultaneously enhancing its economic performance.

Energy Savings and ROI: Quantifying the Benefits

The promise of reduced energy bills is a major driver for adopting reflective roof coatings. Studies conducted between 2010 and 2019 consistently demonstrated significant energy savings. For example, a study by the Lawrence Berkeley National Laboratory found that reflective roofs could reduce cooling energy demand by 10-40% in commercial buildings, depending on climate zone, building characteristics, and coating type. This translates into substantial cost savings over the roof’s lifespan. Furthermore, reduced energy consumption leads to lower greenhouse gas emissions, contributing to a smaller carbon footprint and aligning with corporate sustainability initiatives.

The ROI is compelling, particularly for buildings in warmer climates with high cooling demands. Quantifying commercial roof energy savings requires a nuanced understanding of building physics and local climate data. Beyond the headline figures, sophisticated energy modeling can predict long-term savings with greater accuracy, accounting for factors like occupancy schedules, internal heat gains from equipment, and variations in solar irradiance throughout the year. For instance, a large distribution center operating 24/7 will realize different savings compared to a nine-to-five office building, even with identical reflective roof coatings.

Therefore, a thorough energy audit and simulation are crucial first steps in evaluating the true economic potential of sustainable roofing solutions. The broader cool roof benefits extend beyond direct energy cost reductions and touch upon areas of operational efficiency and asset management. By mitigating thermal stress on the roofing membrane, reflective roof coatings can significantly extend the lifespan of the underlying roof, delaying costly repairs or replacements. This is especially pertinent for commercial buildings with complex roofing systems, where disruptions can impact business operations.

Moreover, cooler roof temperatures can improve the performance of rooftop equipment, such as HVAC units, by reducing their workload and energy consumption. Incorporating these factors into a lifecycle cost analysis further strengthens the economic case for reflective roof coatings. Successful roof coating application is paramount to realizing the projected energy savings and ROI. Improper surface preparation, inadequate coating thickness, or the selection of an inappropriate coating type can all compromise performance and durability. Engaging experienced and certified contractors who adhere to industry best practices is essential. Furthermore, ongoing maintenance, including regular cleaning to remove dirt and debris, is necessary to maintain optimal reflectivity and ensure long-term performance. Investing in proper application and maintenance safeguards the initial investment and maximizes the long-term economic and environmental benefits of sustainable roofing solutions.

Acrylic vs. Silicone vs. Polyurethane: Choosing the Right Coating

The market offers various types of reflective roof coatings, each with its own advantages and disadvantages, demanding a nuanced understanding for optimal selection. Acrylic coatings are a popular choice for commercial properties seeking cost-effectiveness and ease of roof coating application, particularly for buildings with limited budgets. However, their durability and reflectivity may not match that of other options, potentially impacting long-term commercial roof energy savings. Silicone coatings are known for their excellent UV resistance and waterproofing properties, making them a durable option that maintains its reflectivity over time.

This is particularly beneficial in regions with intense sunlight or heavy rainfall, contributing significantly to cool roof benefits and reducing the need for frequent maintenance. Polyurethane coatings provide superior abrasion resistance and flexibility, ideal for roofs subject to heavy foot traffic, such as those with rooftop HVAC systems requiring regular servicing, or buildings prone to structural movement. Cost-effectiveness varies significantly, with acrylic generally representing the least expensive initial investment, while silicone and polyurethane command higher upfront costs but often deliver superior long-term value through extended lifespans and reduced maintenance.

The choice also hinges on the specific demands of the commercial roof and the building’s operational needs. For instance, a warehouse with minimal foot traffic might find acrylic coatings sufficient, whereas a hospital roof with constant equipment servicing would benefit from the resilience of polyurethane. Detailed lifecycle cost analyses, factoring in material costs, application expenses, and projected maintenance, are essential for making informed decisions regarding sustainable roofing solutions. Environmental impact also differs among these reflective roof coatings, with some formulations containing volatile organic compounds (VOCs).

Opting for low-VOC or water-based coatings minimizes environmental harm and contributes to a healthier indoor environment for building occupants. Furthermore, consider the embodied energy of the coating materials themselves; some manufacturers prioritize sustainable sourcing and production practices, further enhancing the environmental profile of their products. Selecting reflective roof coatings that align with broader sustainability goals, such as LEED certification or corporate social responsibility initiatives, demonstrates a commitment to environmental stewardship and contributes to a more sustainable built environment. Careful consideration of these factors is crucial for selecting the best coating for a specific building and budget, ensuring both economic and environmental responsibility.

Application Techniques: Ensuring a Lasting Finish

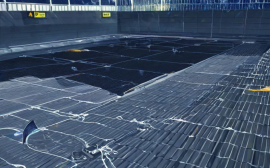

Proper application is paramount for realizing the full potential of reflective roof coatings and ensuring their longevity, a critical factor in sustainable roofing solutions. Surface preparation is not merely a preliminary step; it’s the foundation upon which the entire system rests. The roof must undergo a meticulous cleaning process, removing all traces of dirt, debris, algae, and existing coatings that could compromise adhesion. Commercial roof energy savings hinge on this initial phase, as a poorly prepared surface will inevitably lead to premature coating failure and diminished reflectivity.

Addressing any existing damage, such as cracks, blisters, or ponding areas, is equally crucial before proceeding with the roof coating application. Achieving optimal thickness and reflectivity typically necessitates multiple coats, each applied with precision and care. The specific number of coats and application rate will depend on the type of reflective roof coatings used, the substrate material, and the desired performance characteristics. Application techniques vary, ranging from airless spraying for large, open areas to rolling or brushing for intricate details and flashing.

Regardless of the method, consistency is key. Uneven application can result in variations in reflectivity and premature wear, undermining the cool roof benefits. Strict adherence to the manufacturer’s specifications is non-negotiable for maximizing performance and warranty coverage. Selecting a qualified and experienced contractor is perhaps the most critical decision in the entire process. The nuances of roof coating application demand specialized knowledge and skill. Look for contractors with certifications from reputable organizations and a proven track record of successful reflective roof coating installations. A skilled applicator understands the importance of proper surface preparation, precise mixing ratios, and environmental conditions that can affect adhesion and curing. Furthermore, they can assess the existing roof structure and recommend the most appropriate coating system for optimal performance and durability, ensuring that the investment in sustainable roofing solutions yields maximum returns. A poorly executed roof coating application can negate the intended benefits and lead to costly repairs or even complete re-application.

Common Challenges: Addressing Application and Maintenance Issues

While reflective roof coatings offer numerous benefits, they are not without their challenges, particularly in the demanding world of commercial roofing. One common issue is dirt accumulation, a gradual process that significantly reduces reflectivity over time, thereby diminishing commercial roof energy savings. Regular cleaning, ideally with specialized equipment and environmentally friendly detergents, is necessary to maintain optimal performance and realize the full spectrum of cool roof benefits. Ponding water, often a consequence of inadequate roof slope or clogged drainage systems, can also damage coatings, leading to premature failure and costly repairs.

Selecting a coating with high water resistance and ensuring proper drainage are crucial preventative measures that fall squarely within responsible roof maintenance practices. Another challenge lies in the compatibility of reflective roof coatings with existing roofing materials. Not all coatings adhere equally well to every surface. For instance, applying a silicone coating directly to an aged asphalt roof without proper preparation can lead to delamination and compromised performance. A primer, specifically designed for the existing substrate, may be necessary to ensure proper adhesion and long-term durability.

Careful assessment of the existing roof, including a thorough inspection of its composition and condition, is essential for selecting a compatible coating and guaranteeing the success of the roof coating application. This pre-application diligence is a hallmark of sustainable roofing solutions, preventing material waste and maximizing the lifespan of the new reflective layer. Beyond application challenges, maintaining the long-term integrity of reflective roof coatings requires proactive monitoring and maintenance. Small cracks or blisters, if left unaddressed, can quickly escalate into larger problems, compromising the coating’s ability to reflect sunlight and protect the underlying roof membrane. Implementing a regular inspection schedule, ideally twice a year, allows for early detection and repair of any damage. Furthermore, the presence of vegetation, such as algae or moss, can also diminish reflectivity and contribute to coating degradation. Regular cleaning and the application of algaecides can help prevent these issues and ensure the continued effectiveness of the reflective roof coating, contributing to sustained commercial roof energy savings and the overall sustainability of the building.

Long-Term Durability: Maximizing Lifespan and Performance

The long-term durability of reflective roof coatings is a critical consideration for any commercial building owner seeking to maximize their investment in sustainable roofing solutions. While the lifespan of these coatings is influenced by factors such as the specific coating chemistry (acrylic, silicone, polyurethane, etc.), the quality of the roof coating application, and the prevailing environmental conditions, proactive measures can significantly extend their service life and maintain their cool roof benefits. Acrylic coatings, generally the most economical, typically offer a lifespan of 5-10 years, while higher-performing silicone and polyurethane options can reliably last 10-20 years or even longer with proper care.

Understanding these differences is crucial for making informed decisions aligned with budgetary constraints and long-term performance goals. Beyond the inherent properties of the coating itself, the substrate to which it’s applied plays a vital role in longevity. A properly prepared and maintained roof surface is essential for optimal adhesion and performance. Prior to roof coating application, a thorough inspection should identify and address any existing issues such as cracks, blisters, or ponding water. Addressing these problems prevents premature coating failure and ensures a uniform, durable finish.

Furthermore, the expertise of the application team is paramount; improper mixing, inadequate film thickness, or failure to properly clean the surface can all compromise the coating’s lifespan and negate potential commercial roof energy savings. Regular maintenance is also indispensable for maximizing the lifespan and effectiveness of reflective roof coatings. Periodic cleaning to remove dirt, debris, and biological growth is essential for maintaining high solar reflectance. According to the Cool Roof Rating Council (CRRC), even a slight reduction in reflectivity can significantly impact energy savings.

Simple tasks like power washing or using a mild detergent can restore the coating’s reflective properties. Additionally, prompt repairs of any minor damage, such as small cracks or punctures, can prevent water intrusion and further deterioration. Finally, carefully examine the warranties offered by manufacturers, paying close attention to the terms and conditions, as a longer warranty period often reflects greater confidence in the product’s durability and performance. Investing in high-quality reflective roof coatings coupled with diligent maintenance practices translates to sustained energy savings and a reduced environmental footprint for commercial buildings.

Case Studies: Real-World Examples of Success

Several case studies showcase the successful implementation of reflective roof coatings, demonstrating their tangible benefits across diverse commercial settings. For instance, a large retail chain in California implemented a reflective roof coating program across its stores, resulting in an average commercial roof energy savings of 20% per store. This initiative not only reduced the company’s carbon footprint but also significantly lowered operational expenses, showcasing the powerful intersection of sustainability and profitability. Such large-scale adoption highlights the feasibility and effectiveness of reflective roof coatings as a key component of sustainable roofing solutions for businesses with multiple locations.

The success hinged on selecting a high-quality coating with proven reflectivity and durability, coupled with professional roof coating application techniques to ensure optimal performance. A manufacturing facility in Texas experienced a significant reduction in cooling costs after applying a reflective coating, along with improved indoor comfort for employees. Prior to the application, the facility struggled with excessive heat gain, leading to high air conditioning usage and employee discomfort, directly impacting productivity. The implementation of cool roof benefits, including a cooler roof surface and reduced heat transfer into the building, translated into a more comfortable and efficient work environment.

This case underscores the importance of considering not only energy savings but also the human element when evaluating the ROI of reflective roof coatings. Furthermore, it emphasizes the need for a thorough assessment of the existing roof condition and specific environmental challenges before selecting and applying a reflective coating system. Beyond individual examples, broader industry data supports the positive impact of reflective roof coatings. A meta-analysis of several studies, including research published in “Energy and Buildings,” reveals a consistent trend of energy savings ranging from 10% to 40% depending on climate, building type, and coating characteristics. These findings underscore the importance of considering the specific context when projecting potential savings. Factors such as roof insulation levels, building orientation, and local weather patterns all play a role in determining the actual energy reduction achieved. Therefore, a comprehensive energy audit and simulation modeling are crucial steps in maximizing the benefits of reflective roof coatings and optimizing their contribution to sustainable roofing solutions.

Environmental Impact: Beyond Energy Savings

The environmental impact of reflective roof coatings extends far beyond the readily apparent commercial roof energy savings. While the direct reduction in energy consumption demonstrably lowers greenhouse gas emissions from power plants and mitigates urban heat island effects, a more holistic assessment reveals further benefits. The decreased demand for electricity translates into less reliance on fossil fuels, contributing to improved air quality and reduced acid rain. Furthermore, the mitigation of the urban heat island effect lessens smog formation, improving respiratory health in densely populated areas.

Choosing reflective roof coatings, therefore, represents a proactive step towards a healthier environment for communities. Increasingly, manufacturers are embracing sustainable practices in the production of reflective roof coatings. Some cool roof benefits now stem from the incorporation of recycled materials, such as post-consumer plastics or reclaimed rubber, into the coating matrix. This reduces the demand for virgin resources and diverts waste from landfills. Moreover, innovations in bio-based polymers are leading to the development of coatings with a lower carbon footprint.

Responsible manufacturers are also prioritizing the reduction of volatile organic compounds (VOCs) in their products, minimizing air pollution during roof coating application and throughout the coating’s lifespan. This commitment to environmental stewardship is transforming the reflective roof coating industry. However, a comprehensive environmental analysis must also consider the end-of-life management of reflective roof coatings. While some coatings can be reapplied or recoated, eventually, they will require disposal. Traditional disposal methods, such as landfilling, can pose environmental risks. Therefore, exploring options for recycling or repurposing these materials is crucial. Research is underway to develop methods for breaking down coatings into their constituent components for reuse in other applications. Furthermore, proper maintenance and timely repairs can significantly extend the lifespan of reflective roof coatings, reducing the frequency of replacements and minimizing waste. A lifecycle assessment approach is vital for ensuring that the adoption of sustainable roofing solutions truly minimizes environmental impact.

The Future of Cool Roofs: A Sustainable Investment

Reflective roof coatings represent a viable and increasingly attractive solution for commercial buildings seeking to reduce energy costs, improve sustainability, and extend roof lifespans. While challenges exist, careful planning, proper application, and ongoing maintenance can mitigate these issues. The long-term ROI and environmental benefits make reflective roof coatings a compelling investment for businesses looking to create a more sustainable and profitable future. As technology advances and regulations become stricter, expect to see even greater adoption of reflective roof coatings in the years to come, solidifying their place as a cornerstone of sustainable building practices.

The future of commercial roofing is inextricably linked to the evolution of sustainable roofing solutions, and reflective roof coatings are leading the charge. Their ability to significantly reduce commercial roof energy savings, coupled with increasing regulatory pressure to adopt energy-efficient technologies, positions them as a key component in achieving broader sustainability goals. Innovations in material science are constantly improving the performance and durability of these coatings, making them an even more attractive option for building owners.

Looking ahead, the integration of smart technologies with reflective roof coatings promises to further enhance their effectiveness. Imagine roof coatings embedded with sensors that monitor temperature, humidity, and reflectivity, automatically adjusting to optimize energy performance in real-time. This data-driven approach will allow for more precise management of cool roof benefits, maximizing energy savings and minimizing environmental impact. Furthermore, advancements in roof coating application techniques, such as drone-based spraying and self-healing coatings, are poised to streamline the installation process and extend the lifespan of these systems.

These developments will not only reduce labor costs but also minimize disruptions to building operations during installation and maintenance. Ultimately, the widespread adoption of reflective roof coatings hinges on continued education and awareness among building owners, contractors, and policymakers. By highlighting the tangible economic and environmental advantages of these systems, we can accelerate their integration into mainstream commercial building practices. Case studies demonstrating substantial cost savings and reduced carbon footprints are crucial in showcasing the real-world impact of reflective roof coatings. Moreover, government incentives and tax credits can further incentivize adoption, making sustainable roofing solutions more accessible and affordable for businesses of all sizes. As the demand for energy-efficient and environmentally responsible building solutions continues to grow, reflective roof coatings are poised to play an increasingly vital role in shaping the future of the built environment.